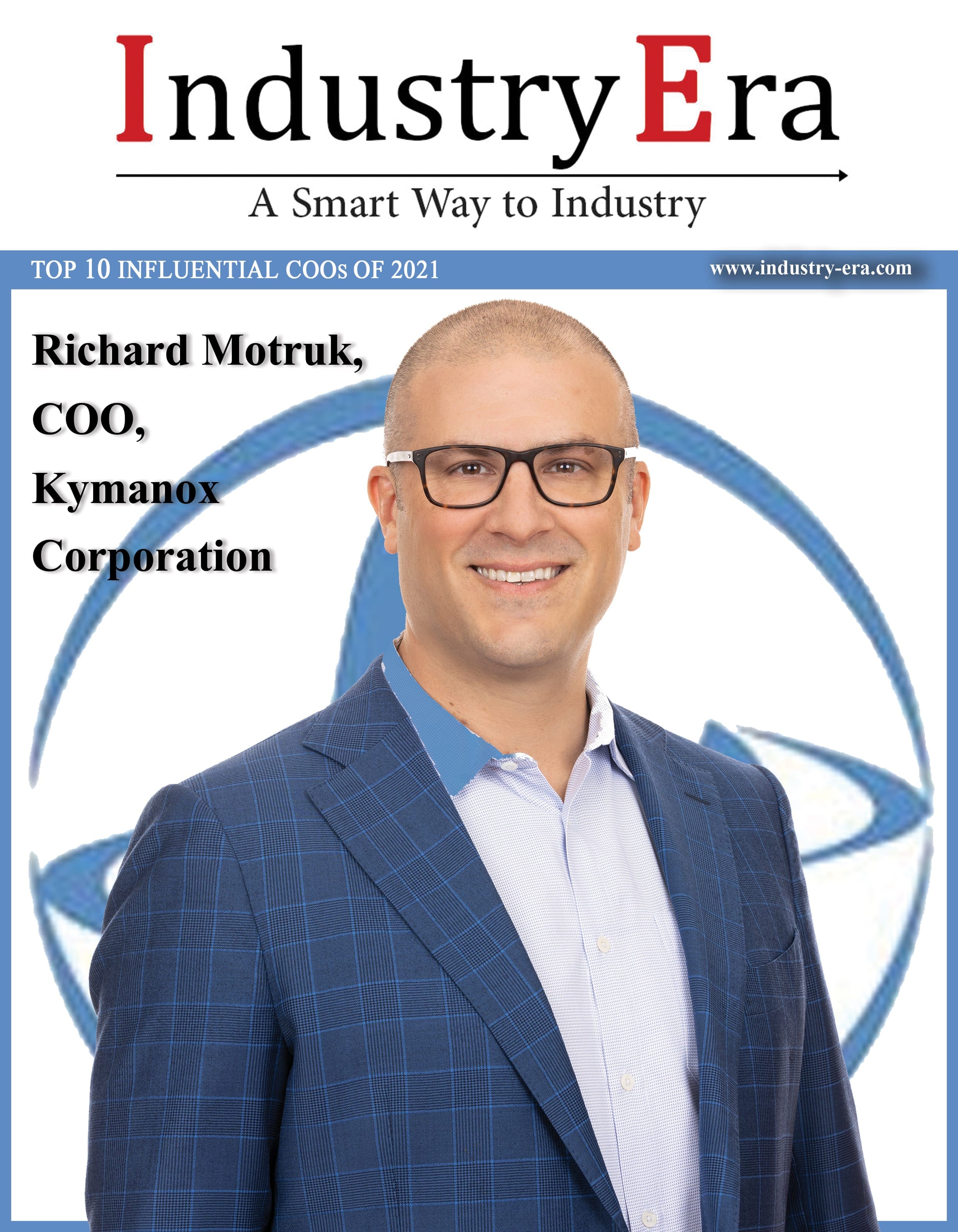

Jason Van der Schyff

Chief Operating Officer of SoftIron

“Creating Asymmetric Advantage”

Jason Van der Schyff’s skill at translating good ideas into actionable plans makes for an agile, innovative environment. By combining vision unencumbered by “how things are done” with a practical understanding of what is needed to do them differently, Jason creates momentum that carries SoftIron forwards with every new initiative. It’s something he terms creating “Asymmetric Advantage” for a business, a philosophy that he shared in his recently published book of the same name. Through his own experiences and consultation work for blossoming startups, Jason has developed an industry perspective that identifies the typical needs of a young tech business, the pitfalls, and the best times to take risks. His understanding of the industry allows the team to identify niches that they are primed to fit and circuit-break any activities that aren’t delivering value to the business. Too often, younger tech companies are driven to push for quick wins over building a solid foundation of quality products and time-honed expertise. Jason has helped SoftIron build that solid foundation, and the ‘quick wins’ have always been aligned with this underlying, long-term thinking.

There are many tools, techniques, and authentication methods on the market today to assist savvy businesses with mitigating software-related security risks. However, hardware infiltration can be much more difficult to detect, and significant hardware manufacturers today largely outsource the manufacturing (and sometimes even the design) of their hardware to third parties. They frequently have no oversight into the exact factory location or process involved in creating their hardware. This introduces numerous supply chain risks for hardware trojan hijacking devices on the factory floor or in transit. Customers are required to put their blind trust in their vendors that hardware has not been tampered with during the supply chain process and that the manufacturers of that hardware are also trustworthy. But a full audit can never be conducted when there are so many unknowns in the process.

Conversely, because SoftIron manufactures everything from the component level up in a tightly controlled onsite manufacturing environments owned and operated by SoftIron, they can offer hardware with a complete forensic chain of accountability. That means customers can verify through an audit that the products they receive are identical to those that left SoftIron’s factory floor. This transparency is unmatched by any other commercial vendor on the market today. For organizations that prioritize secure, intact data, SoftIron hardware offers a level of auditability that uniquely puts the power back into the customer’s hands, a vital part of the puzzle for creating a ‘zero trust’ secured IT solution.

In an instance, Vocus New Zealand selected SoftIron’s HyperDrive storage solution to form the backbone of its new DataHub storage infrastructure, an object storage cloud storage service that will offer mission-critical, secured, and reliable infrastructure for enterprises and government departments. As a major telecom services provider, Vocus has more than 4,200km of fibre in the ground in New Zealand, delivering sophisticated, high-performance network and cloud solutions. Vocus chose SoftIron HyperDrive as the foundation of DataHub due to its unparalleled, task-specific performance running the open source storage software, Ceph, which it has been built to optimize.

SoftIron’s foundational pillars are key to the company’s success, including:

● Designed, not assembled - They design products from the ground up, not from generic hardware sub-assemblies and pre-compiled code.

● Secure provenance – The product design, hardware, software, and realization process are transparent for audit, enabling customers to assert their own risk on deploying SoftIron products in their mission-critical infrastructure.

● Edge manufacturing - Their mission is to build and optimize a manufacturing capability that can act globally when needed and manufacture and deliver complete products close to customers. This shortens their and customers’ supply chain processes and makes them visible and more resilient.

● Globally distributed, locally embedded - They build out their teams in any location or function. Embedding these teams in the economies they operate within benefits their employees, customers, and the broader community they serve.

The company wants to focus on its growth plans for locally embedded, globally-connected manufacturing facilities for the days to come. “We have plans in place to grow the footprint of our factory in North America, we are opening a new factory in Sydney, Australia and we have plans in place to increase our presence in Singapore and Europe.” IE

Company

Management

Jason Van der Schyff

Chief Operating Officer of SoftIron

Description

We’re making software-defined storage simple. SoftIron’s mission is to create the world’s finest storage solutions for the modern-day enterprise. And by finest, we mean exceptionally high-performing, scalable, flexible, reliable and efficient products that are really easy to use.